Autonomous Mobile Robot for Warehous Industries

Developed an AMR prototype with autonomous navigation in indoor environments.

This project demonstrates the design and implementation of an Omni-Wheeled Autonomous Mobile Robot (AMR) tailored for automating repetitive and time-intensive warehouse operations. The solution integrates cutting-edge robotics, SLAM technologies, and efficient hardware to embody the principles of Industry 4.0.

Hardware and Mechanical Design

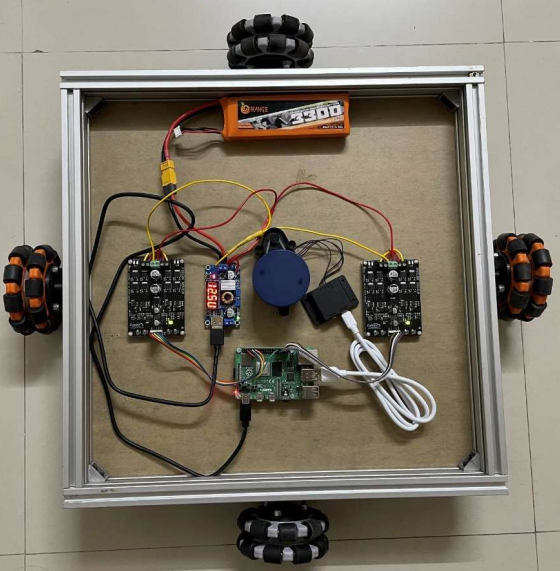

Components Utilized:

- Raspberry Pi 4B: Acts as the central processing unit for controlling navigation and decision-making.

- 360 degree LiDAR Sensor: Facilitates environment scanning for mapping and obstacle detection, ensuring efficient path planning.

- Omni-Wheels: Provide multidirectional mobility, enabling the robot to maneuver smoothly in tight and dynamic warehouse environments.

- Motor Drivers: Control wheel movement, translating navigation commands into precise actions.

- Power System: A 2200mAh Li-ion battery ensures sustained operation, stabilized by power regulators for consistent performance.

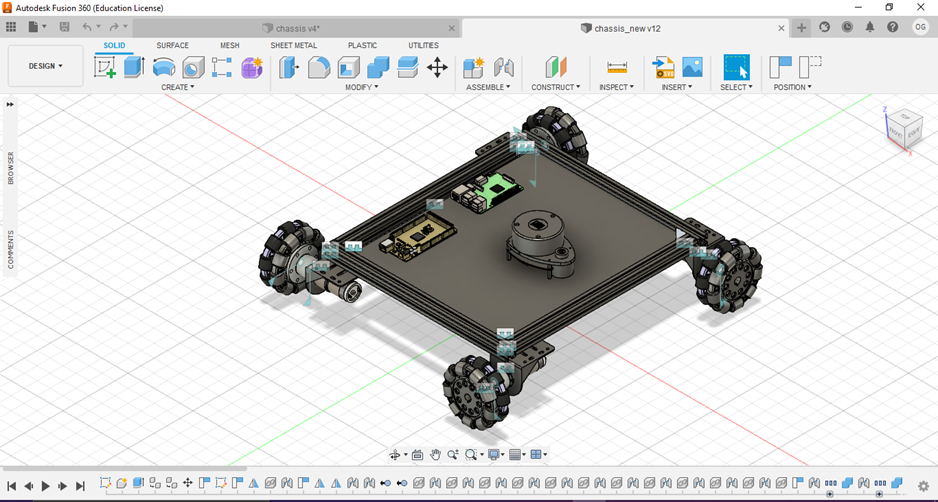

Mechanical Construction:

- The robot was designed with a focus on structural durability and modularity, simplifying maintenance and component replacement.

- Integration of URDF models and 3D drawings allowed for simulation testing of robot movement and behavior prior to physical deployment.

Software Integration

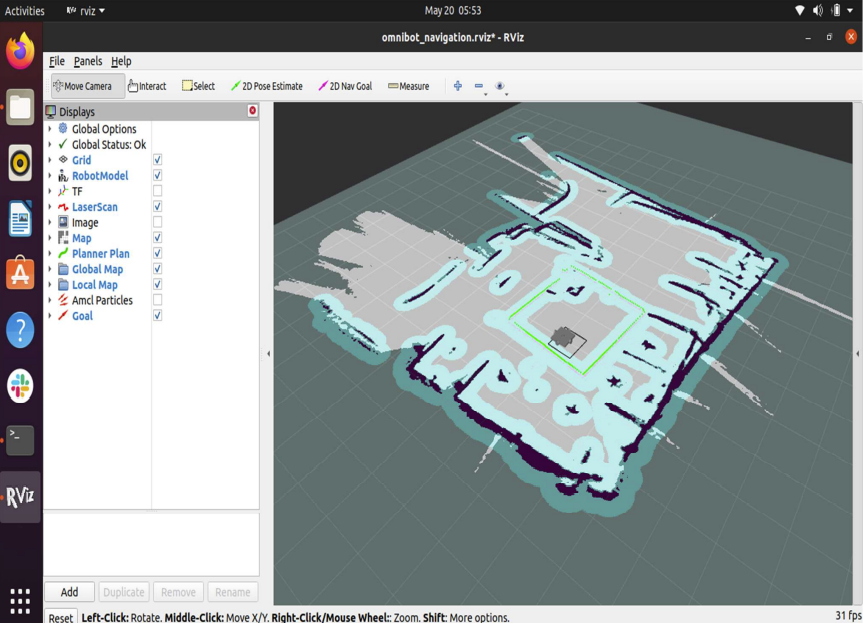

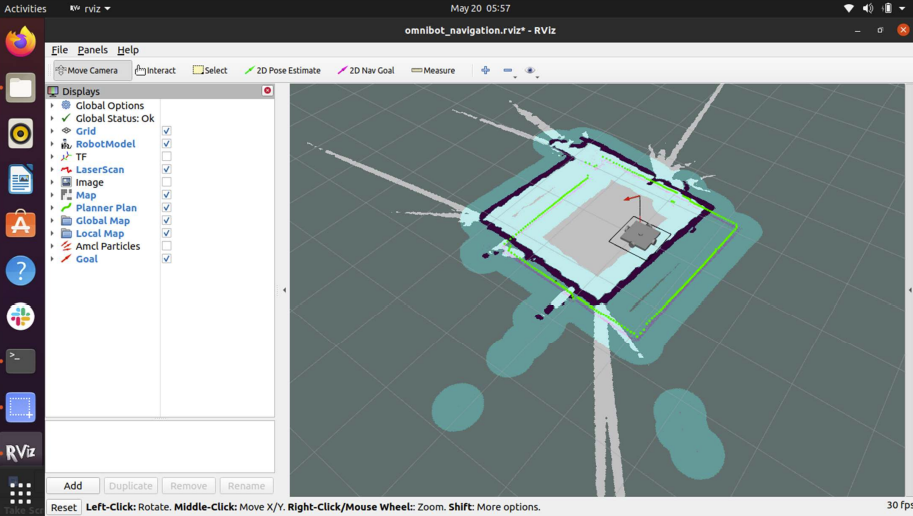

Simultaneous Localization and Mapping (SLAM):

- SLAM algorithms enable the robot to construct detailed indoor maps and localize itself within the environment. This is critical for real-time path planning and navigation.

- The LiDAR sensor provides high-resolution environmental data for precise mapping.

Caption photos easily. On the left, a road goes through a tunnel. Middle, leaves artistically fall in a hipster photoshoot. Right, in another hipster photoshoot, a lumberjack grasps a handful of pine needles.

This image can also have a caption. It's like magic.

Path Planning and Navigation:

- Real-time pathfinding algorithms guide the robot efficiently between locations, avoiding static and dynamic obstacles.

- Integrated control systems ensure smooth transitions and accurate alignment during operations. Interfacing and Communication:

Potential Applications

- Warehousing: Automating goods movement and inventory management.

- Manufacturing: Streamlining material handling between production stages.

- Healthcare: Transporting medical supplies in large facilities.

This project highlights the transformative potential of robotics in industry, particularly for small-scale businesses looking to embrace automation.